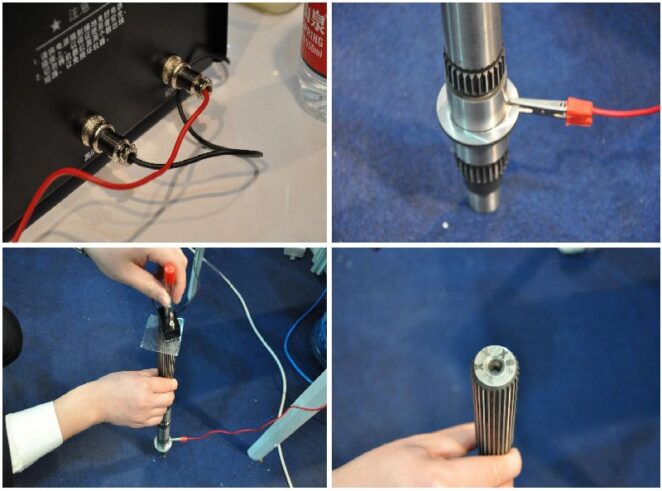

Electro-chemical etching machines are one of the most common machine types in manufacturing, used to create patterns on substrates such as metal sheets. In this 2024 guide, we’ll take a look at how these machines work and discuss some of the potential uses for them in the future.

What is an Electro-Chemical Etching Machine?

An electro-chemical etching machine is a device that uses an electric current to remove material from a substrate. An electro-chemical etching machine works by passing an electric current through the substrate and the etching solution. The electric current causes the material to be removed from the substrate, which in turn produces a pattern on the surface of the substrate.

There are several different types of etching machines, but all of them use an electric current to remove material from a substrate. The type of etching machine used will determine the shape of the pattern that is produced.

How Does an Etching Machine Work?

An etching machine is a device used to create a negative image on a substrate by using an acid or a base. The machine works by bringing the acid or base up to the surface of the substrate, which causes the material to etch away.

The exact mechanism behind how an etching machine works is still not fully understood, but it is believed that the action of the acid or base on the surface of the substrate causes localized liquidation and vaporization of material molecules. This in turn creates gas bubbles, which cause the material to be pulled away from the substrate. Chemical etching is a very powerful tool and can be used to create intricate and detailed images.

Types of Electro-Chemical Etching Machines

An electro-chemical etching machine is a machine that uses electricity and chemicals to remove material from a surface. It is one of the most common types of machines used in manufacturing and engineering.

There are several types of electro-chemical etching machines, but all of them work in the same way. The machine has a cathode (an electrode that is an anode in reverse) and a target or substrate. The cathode is connected to the power supply, and the target or substrate is connected to the anode.

The machine starts by supplying electricity to the cathode. This causes the electrons in the cathode to become excited, or roused. The excited electrons flow towards the target or substrate, where they cause damage to the surface.

The damage caused by the electrons can be removed using various chemicals. These chemicals react with the molecules on the surface of the target or substrate, removing them from the surface. As this process proceeds, the target or substrate becomes less and less visible.

Advantages of an Etching Machine

An etching machine is a tool that is used to create a variety of patterns on metal. It has a number of advantages and few disadvantages, which are summarized below.

Advantages:

- An etching machine is simple to use and can be operated by a relatively unskilled user.

- It is fast and efficient, making it ideal for creating small-scale patterns or details.

- Etching machines are relatively cheap to buy and run, making them affordable for small businesses or individual hobbyists.

- They are resistant to corrosion, making them suitable for use in harsh environmental conditions.

- Etching machines can be used to create a wide range of textures and finishes on metal surfaces.

- They can be used to mark or emboss metal objects, which makes them useful for decorative purposes.

- They are easy to clean and maintain, making them ideal for use in industrial settings or manufacturing plants.

- Etching machines produce a high-quality finish on metal objects, which is resistant to wear and tear.

- They are versatile enough to be used in a variety of industries, such as the automotive industry or the aerospace industry.

Disadvantages of Using an Etching Machine

An electro-chemical etching machine is a type of machine used to remove material from a surface. Etching is a process that uses an electric current to remove material from a metal or other hard surface.

There are several advantages of using an etching machine over other methods. First, etching is a very fast process. It can be used to remove large amounts of material in a relatively short amount of time. Second, it is an environmentally friendly process. Etching does not require any special tools or chemicals, which means it can be used on many different surfaces. Finally, etching is a reliable process. If the machine is properly maintained, it will work without fail.

Electrochemical Etching Machine Vs Laser

The main difference between an electrochemical etching machine and a laser etching machine is that an electrochemical etching machine uses an electric current to remove material by chemically changing the surface of the material. A laser etching machine, on the other hand, uses a beam of light to remove material.

Another main difference between an electrochemical etching machine and a laser etching machine is that an electrochemical etching machine can be used to etch a variety of materials, while a laser etching machine is best suited for etching certain types of materials. Additionally, an electrochemical etching machine is less expensive than a laser etching machine, but both machines can be used to create the same types of products.

Overall, the main difference between an electrochemical etching machine and a laser etching machine is that a laser etching machine is faster and more precise than an electrochemical etching machine.

Conclusion

In this 2024 guide, we will be discussing how an electro-chemical etching machine works and its various advantages. By understanding how the machine works, you can make more informed decisions when purchasing one, or better yet, learn more about what to look for in a quality etching machine. We will also provide some tips on how to use an etching machine so that your prints come out looking their best. Thanks for reading!